Industrial training methods have been radically transformed by the advent of Virtual Reality (VR) technology. One remarkable example of this revolution is the pioneering collaboration between First Polymer Training and Mersus Technologies. Together, we’ve redefined the field of injection moulding by creating a groundbreaking VR-based industrial training platform.

Redefining Training in Injection Moulding

For twenty-five years, First Polymer Training has been at the forefront of plastics training, providing both theoretical and practical knowledge in injection moulding. They recognised the tremendous potential of VR technology to augment their existing industrial training methods, providing an immersive learning experience.

The core objective was straightforward: enable trainees to interact with a virtual machine before dealing with real-world equipment, thereby eliminating the risk of breaking or damaging expensive moulds.

Embracing VR in Industrial Training

Introducing VR into the curriculum of First Polymer Training was met with remarkable enthusiasm. Trainees reported that the virtual experience bore a striking resemblance to operating an actual machine, making VR an effective tool for risk-free learning in industrial training.

The virtual simulation was so compelling that the trainees found themselves immersed in the VR experience, losing track of their actual surroundings. This safe and controlled environment allowed them to concentrate on understanding the machine’s complex operations and processes.

It offers you the opportunity to have a trial run, knowing that you’re not going to break anything – Jason, Trainee

Enhancing Safety and Understanding in Industrial training

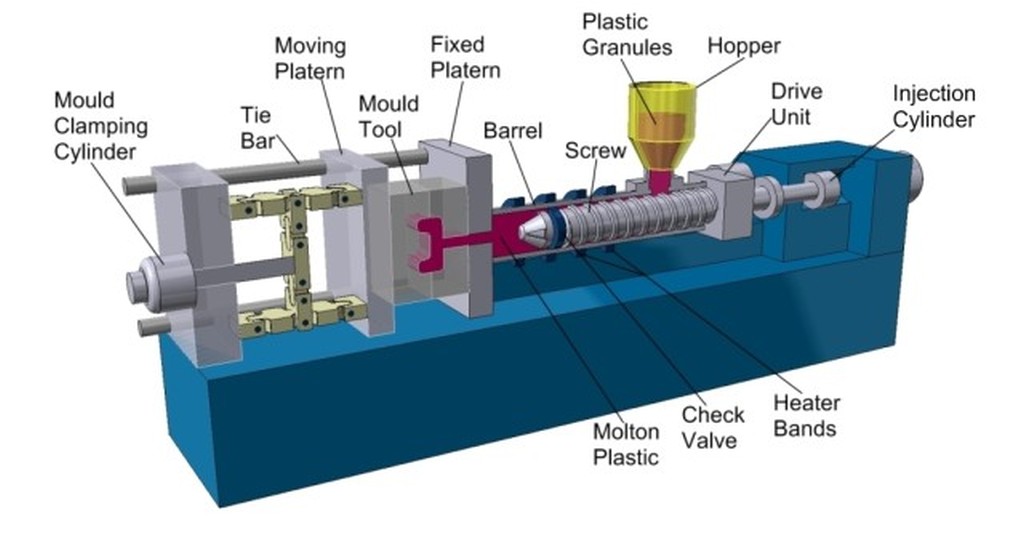

An important advantage of VR in industrial training, as highlighted by the trainees, was the opportunity to observe the machine’s internal processes without the associated hazards. They could visually grasp how the screw moves within the barrel, a critical yet dangerous operation in a real machine, thereby enhancing their understanding of how the machine drives material forward.

Building Confidence

For fresh graduates entering the workforce, operating expensive machinery can often be nerve-wracking. However, the integration of VR into training offers a risk-free environment for practice, enhancing the learners’ comfort and familiarity with the equipment. This confidence-boosting tool allows trainees to become more relaxed, significantly improving their performance and overall learning experience.

Improving the Training Experience

By incorporating VR into their training program, First Polymer Training effectively enriched their instructional delivery. They could divide trainees between the VR headsets and actual machines, diversifying the learning experience and optimising resource utilisation.

The VR tool expedited learning, ensuring that employees’ time away from the workplace for industrial training was maximised. The immersive experience also reinforced the learning process, facilitating a deeper understanding and long-term retention of knowledge.

It gives us an extra feature to our training delivery, and also helps embed the learning – Catherine Collins, Network Manager, First Polymer Training Skillnet

A Rewarding Partnership

First Polymer Training expressed immense satisfaction with their partnership with Mersus as their VR technology provider. They acknowledged the team’s professionalism and responsiveness, which played a crucial role in translating their vision into reality. The development of the VR platform was described as an “amazing” process, with new modules added each week, enhancing the scope of industrial training.

Future Opportunities in Industrial Training

The integration of VR technology is viewed as a launchpad for further enhancements in First Polymer Training’s curriculum. It’s expected that this technology will play a key role in supporting learning across all their member companies, shaping the future of industrial training.

As industries continue to evolve, the use of VR in industrial training is becoming increasingly significant. First Polymer Training’s innovative approach illustrates how embracing such technology can redefine traditional practices, providing a safe, immersive, and enriching learning experience for trainees in the field of industrial training.